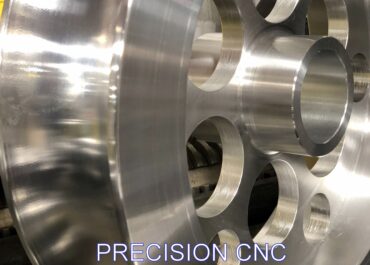

Milling – Turning – Wire EDM - Precision Grinding

We offer complete machining services – parts to your prints / parts from your sample. Our shop is fully equipped to handle all of your machining needs.

RECENTLY ADDED

-Keyence XM5000 Portable CMM with repeatable measurements down to 0.0003”

—2024 Doosan CNC Lathe 5100LMB – 35.4” swing over bed, 27.16” over carriage, 25.6” capacity turning. 78.8” maximum turning length, 90.82” between spindle nose and tailstock center, 6.55” bore through chuck, mill-drill capability reduces need for secondary operations, programmable hydraulic tailstock and self-centering steady rest

-2024 Doosan CNC Lathe 5100XLMB–34.25”swing over bed,27.16”over carriage,25.6”capacity turning.119.2”maximum turning length,131”between spindle nose and tailstock center,6.55”bore through chuck, mill-drill capability reduces need for secondary operations, programmable hydraulic tailstock and self-centering steady rest

– 2023 Mitsubishi Wire EDM MV2400-ST Workpiece Capacity: 41.3” x 32.3” x 16.5”

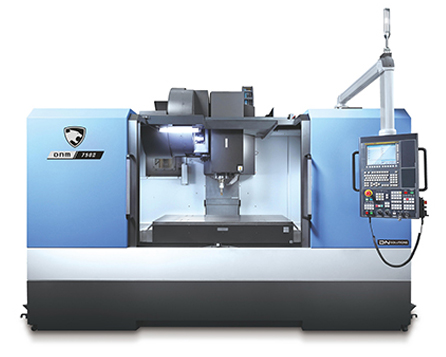

– 2022 Doosan CNC mill 48” x-axis, 24” y-axis, 20.1” z-axis with Renishaw probe

– 2021 Fermat CNC horizontal boring mill with 4th axis – 157.5″x-axis x 98.4″y-axis x 59.1″z-axis x 31.5″ spindle travel, 22 ton table capacity, 165.4” of swing on 4th axis

– CNC Lucas Horizontal Boring Mill – 120″ x-axis, 98″ y-axis, 48″ z-axis, 29″ spindle travel with a large open 20 ton capacity table.

– 2019 Doosan CNC Mill with 4th axis

– 2019 Doosan CNC lathe with live milling and bar feeder

FAST AND DEPENDABLE

PROJECTS

– Manufacturing up to 5,000 parts

– Turning up to165.4” diameter

– CNC milling up to 157.5”x 98.4”x 60” with full 4th axis capabilities and probing capabilities

– State of the art technology – CNC milling & turning utilizing 3D modeling, CAM programming and the newest/best CNC equipment

– Experience in all materials – Carbon Steels, Tools Steels, Castings, Stainless, Aluminum, Specialty Alloys, Plastics (UHMW, Teflon, Etc.) and much more

– OEM Replacement Parts shipped nationwide

– Equipment Repair Machining

– Journal Repairs, boring and bushing, welding up (or metalizing) and machining down of shafts, and more.

– Part Fit and Tolerance Knowledge to Help Insure Proper Clearance and Fit of Parts

– Ability to Machine What Other’s Can’t (Oblique or Large Items, Etc.)

– Largest in-house equipment in Southeast Iowa region

WE WORK HARD TO CREATE VALUE AND OFFER

SOLUTIONS TO YOUR PROJECTS