RECENT ADDITIONS AT HUFFMAN WELDING & MACHINE

2023 Amada Ventis 6KW Fiber Laser – 5’x10’ tables – up to 1 1/2” carbon / 1” stainless steel

2023 Mitsubishi Wire EDM MV2400-ST Workpiece Capacity: 41.3” x 32.3” x 16.5”

Davi CNC 4-roll Roller MCA 2020 6’ wide x 7/16” capacity – can roll cylinders, half moons, and cones

2022 Doosan CNC mill 48” x-axis, 24” y-axis, 20.1” z-axis with Renishaw probe

2021 Fermat CNC horizontal boring mill with 4th axis – 157.5″x-axis x 98.4″y-axis x 59.1″z-axis x 31.5″ spindle travel, 22 ton table capacity, 165.4” of swing on 4th axis

2021 Lincoln Python X Structural Steel Processor with capabilities to cut up to 50 ton/week

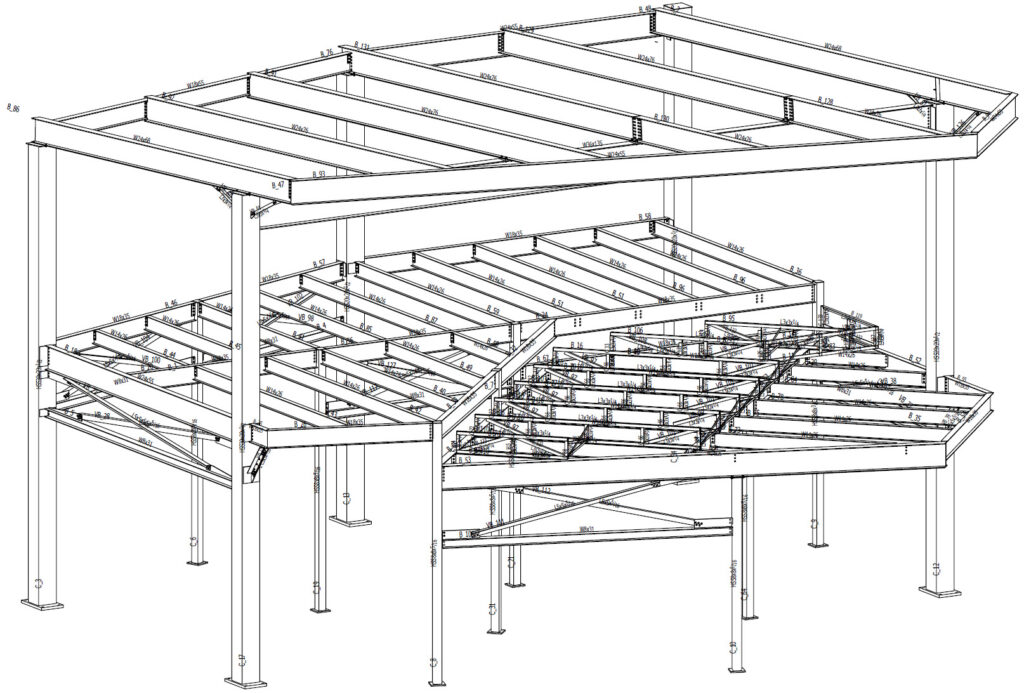

2021 SDS/2 Automated Shop Drawing Software – In-house certified SDS/2 detailer

2021 Accurpress 250 TON x 12’ 7-axis CNC Press Brake

2021 Ercolina TB60-TC CNC Programmable Pipe and Tube Bender

2021 Marvel Precision Saw 20”x25” capacity, 60 deg miter, +/-0.005 shuttle accuracy

2020 Doosan CNC mill with 4th axis

2020 Doosan CNC lathe with LIVE TOOLING and bar feeder

2018 New Lucas CNC horizontal boring mill 120″x-axis x 98″y-axis x 48″z-axis x 29″ spindle travel

332,832 kWH solar field

All new state of the art Lincoln welders with pulse technology

Now with over 65,000 sq feet and up to 10 ton overhead crane capacity

Continued growth since 1971

Team Capabilities

– Founded in 1971 with over 110 employees companywide and 55 at Huffman Welding & Machine, Inc. division with many craftsmen having over 60 years and 100,000+ hours of experience in machining, fabrication, machine building, equipment repair, specialty repair, quality inspection, and material cutting and supply.

Fabrication and Welding

– Lincoln Structural Steel 6 axis processor as noted below under “material cutting”

– MIG, TIG, Stick, Spot – Carbon, Stainless, Aluminum, Specialty Alloys

– On-Site MIG, TIG, and Stick for Stainless and Carbon

– Onsite MIG for Aluminum

– 15+ Welding Power Sources. – We run new Lincoln electric welders with pulse-on-pulse and power mode technology and inverter technology. 500+ amp units and more

– Automatic weld positioners and rollers and other fixturing

– Portable pipe and plate chamfer milling machine

– Bore welder and boring machine 1.9” up to 10” bores

– Nelson stud welder up to ½” dia

– In-house Visual, Dye-Penetrant, and Magnetic Particle Inspection

Plate and Tube – Forming / Rolling / Bending

FORMING – 2020 Accurpress – 7-axis CNC, 250 TON x 12′, 12″ stroke

— Utilizing the world’s most accurate pressbrake and tooling technology

— Precision WILA new standard tooling including goosenecks and roll-a-vee

— Box Brake for light GA box forming

ROLLING – Davi CNC 4-roll Roller MCA 2020 6’ wide x 7/16” capacity – can roll cylinders, half moons, and cones

TUBE BENDING – Ercolina TB60-TC CNC Programmable Pipe and Tube Bender

TUBE ROLLING – Cole-Tuve PK-35 Tube/Round/Angle Roller

Fastening – Spot Welder / Rivnut and other sheet metal fasteners assembly

Material Cutting – CNC Laser, Plasma, Oxyfuel, Structural Processor

– Lincoln PythonX Structural processor – 6 sided processing 36” tall x 60’ long for beams, channels, angles, square and rectangular tubing for all copes, miters, holes, slots, chamfers, etc.

– Amada 6000W Fiber Laser with 5×10 table – up to 1 1/2″ carbon and 1″ stainless thickness capacity

– CNC Plasma and Oxyfuel Table with 6×12 table up to 12″ thick capacity

– Subcontracting partners for waterjet

– Multiple handheld high-powered plasma and acetylene torches and air arc machines

– Pexto Shear – 10′ x 10 ga – 1/4″ x 3′

Saw Cutting

– Marvel Precision Vertical with Miter Cut Bandsaw – VT5063SW fully automatic 20×25″ capacity, 20″ rounds, At 45 deg – 20×17 or 17 on rounds, At 60deg 20×11.25″ or 11.25 rounds. 1 1/2″ blade Flood and mist coolant Position accuracy of +/-0.005 Stock cut lengths for machining of no more than .040″ over machined lengths on large parts

– Automatic-band saws, hot saws, cold saws, special nibblers and material saws, and more.

Painting, Sandblasting and Special Coatings

– Large exhausted wet paint booth

– Various size sandblasters (large capacity for big vehicles/equipment)

– Cleanroom for clean part drying

– In-house spray metalizing

– In-house black oxide coating system

– Subcontracting partners for powder coating, galvanizing, heat treat, plasma coatings, and hard chrome buildup up to .017” and more

In-House Shaft and Journal Repair (Welding & Spray Metalizing)

– Weldup of any shaft end or any diameter with automated weld positioners

– Spray metalizing with buildup capabilities between 3/16″-1/4″

– Bore Welder 1.9” up to 10” bores up to 10″ deep roughly 36″ long outside to outside on faces

– H-frame presses up to 150 ton x 4’ x 8 1/2’ for removal/installation of bushings, bearings, gears and more

Material Handling

– Cranes spanning 275’ long with 18’ hook height / 30 TON capacity

Wire EDM

– 2023 Mitsubishi Wire EDM MV2400-ST Workpiece Capacity: 41.3” x 32.3” x 16.5”

Milling – CNC large horizontal capacity up to 157.5” x 98.4” x 31.5” with 22 ton table capacity and 3 mills with 4th axis including largest new CNC boring mill

– CNC Fermat WFT 13 New 2021 horizontal boring mill with full 4th axis rotary table. 157.5” on x-axis, 98.4” y-axis, 59.1” Z-axis, 31.5 w-axis, Swing of 165.4” diameter on 4th axis with max cutting diameter of 115.2”, 22 ton table with size 70.8”x86.6”, 5.1” cat 50 spindle with 31.5” of travel. 40 tool changer and Fanuc 31iB controller and Renishaw RMP60 probe, and 90 degree rotatable head

– CNC Lucas purchased new 2018 40T1210 horizontal boring mill with 20 ton table capacity and range of 120” x-axis x 98” y-axis, 5.1” Cat 50 spindle with 29” of travel. 32 tool changer and Fanuc 0i-MF controller. 90 degree rotatable head

– Doosan (2) – 1 each 2022 / 1 each 2020 CNC vertical mill – 41.3” x-axis x 22.4” y-axis, 20.1″ z-axis and 4th axis milling with Renishaw OMP60 probe

– 2ea purchased 2017 Acer CNC toolroom mills including 4th zxis CNC capabilities

– Multiple traditional horizontal and vertical mills up to – 4″ spindle, 84″ cross travel, 74” on y-axis, 60″ vertical with a 4” x 36” spindle

Turning – CNC with live tooling for milling and bar feeders / Large Capacity Lathes up to 60”

– Doosan purchased new 2020 CNC lathe with live milling tooling – GT3100M with 28.3″ over bed, 23.2″ over saddle and up to 49″ between centers, turret with hydraulic chuck and bar feeder up to 4″ dia and live tooling for milling, 2800RPM Spindle, 47HP

– Milltronics CNC lathe with 18″ chuck x 24″ of travel x 48″ between centers

– Monarch lathe 60″ dia. x 108″ length (50″ over carriage)

– LeBlond lathe – 48″ x 216″ length

– Using our heavy duty steady rests and rollers we can machined shafts over 35 feet long

– 8+ other lathes for specialty jobs

Precision Grinding

– Blanchard Grinding up to 36″

– Cylindrical Grinding 14″ x 4′

– Surface Grinding 10″ x 2′

HWMI Heat Treat

– Oven Dimensions: Inside 8″ Tall x 11 1/4″ Wide x 16″ Long

– Subcontracting partners for larger items that need heat treat or stress relieving, etc.

Quality and Inspection – ISO 9001:2008 Compliant

– Renishaw OMP60 probe and Renishaw RMP60 probe

– Climate controlled inspection room

– Multiple granite inspection tables

– Full range of precision calibrated micrometers and calipers

– Specialty micrometers for threads, internal measurements

– Precision height gage

– Hardness testers, paint Mil gage

– Subcontract partners for laser and CMM detailed 3rd party inspections

– Fabrication – In-house Visual, Dye-Penetrant, and Magnetic Particle Inspection

– Providing 100% customer satisfaction and quality approved parts since 1971

Floor Space

– Over 65,000 Sq Feet of building. assembly/fabrication capabilities for assemblies over 275′ long. Contact us for all your large fabrications and projects.

Trucking and Delivery

– Full fleet of delivery trucks including box trucks and semi flatbeds

Material Supply and Inventory

– We have much of the material needed for jobs on-hand and available the day of the job.

– Industrial supply inventory at HWMI/HF&H is one of the area’s largest for

jobs on-hand and available the day of the job.

– Industrial supply inventory at HWMI/HF&H is one of the area’s largest for hardware of all grades and types, metal inventory of carbon, stainless, and aluminum, pipe and pipe fittings, hydraulic fittings and custom hose, & more

– 3 Farm and Home retail locations (see www.huffmansfarmandhome.com)